How is the fiber laid into a uniform web in the production of beauty care spunlace nonwovens? What is the impact of this method on the subsequent spunlace reinforcement?

Fiber laying technology: dry web, precise and uniform

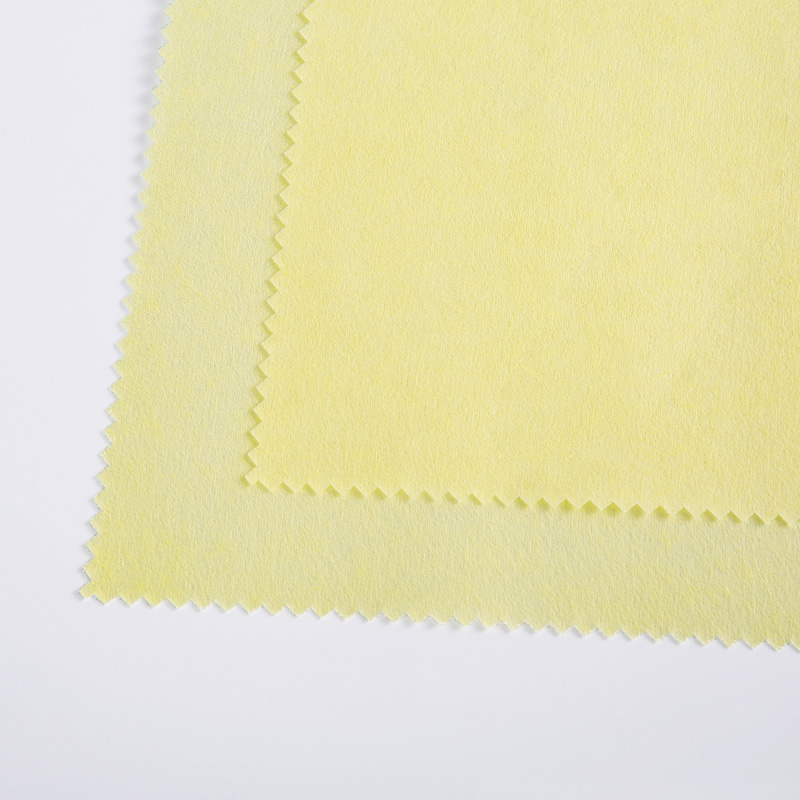

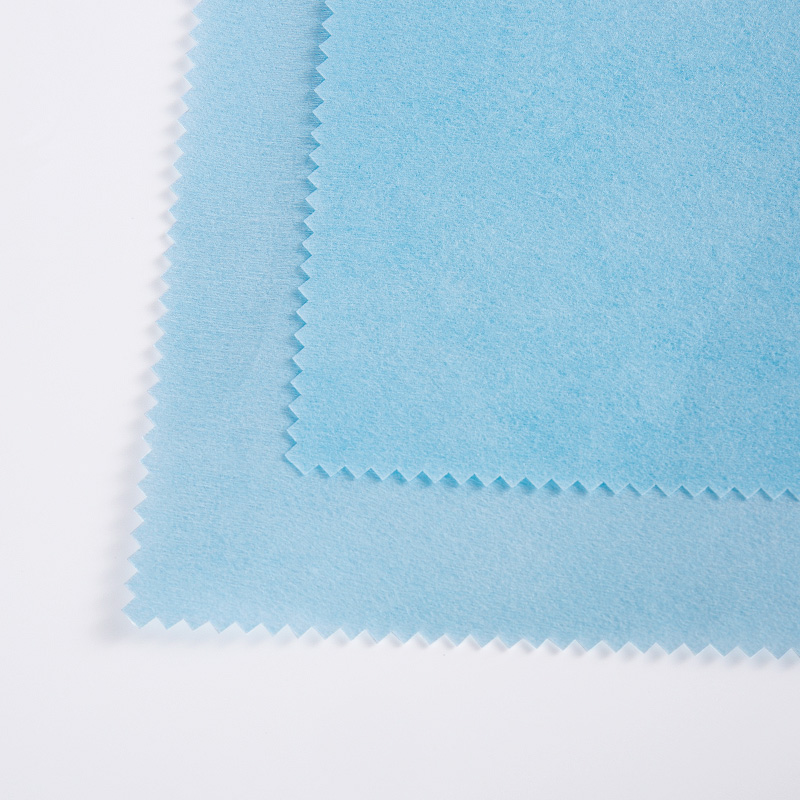

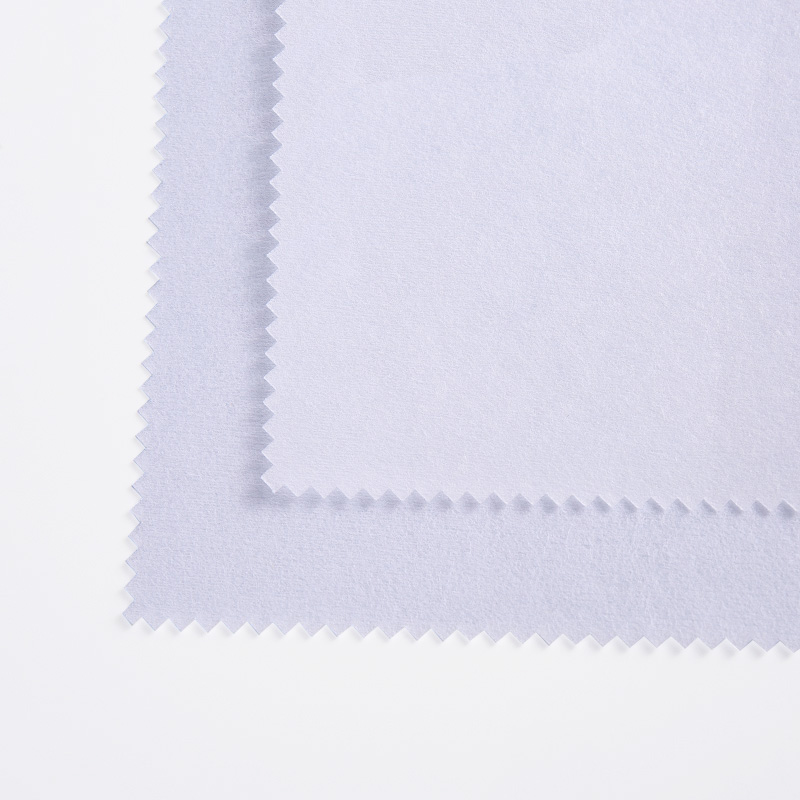

In the production process of beauty care spunlace nonwovens, the uniform laying of fibers is a crucial step. JIELI uses advanced dry web technology, which uses precise mechanical devices to spread pre-treated high-quality fibers (such as polyester fibers, viscose fibers, etc., selected according to customer needs) into a web in a continuous and uniform manner. The specific process includes fiber delivery, opening, mixing, combing and stacking, and each step is carefully designed to ensure the uniform distribution and directional arrangement of the fibers.

Delivery and opening: The raw fiber first passes through an efficient delivery system and enters the opener, where the fiber bundles are dispersed into single fibers through mechanical action, impurities are removed, and the fiber fluffiness and spinnability are increased.

Mixing: Fibers of different types or colors are fully mixed in the mixer to ensure the multi-component characteristics or color uniformity of the final product.

Combing: After fine combing by the carding machine, the fibers are further arranged in parallel to form a preliminary fiber web structure. This process is crucial to improving the uniformity and strength of the fiber web.

Laying: The combed fiber web passes through the web laying machine, and according to the preset thickness and width, the fiber stacking is precisely controlled to form a continuous and uniform fiber web layer, laying a solid foundation for subsequent hydroentanglement reinforcement.

Hydroentanglement reinforcement: efficient consolidation, improved quality

The uniform distribution of fibers achieved by dry web forming technology has a profound impact on the subsequent hydroentanglement reinforcement process. Hydroentanglement reinforcement is a physical reinforcement method that uses high-pressure water flow to spray the fiber web so that the fibers are entangled with each other to form a stable three-dimensional structure, thereby improving the strength, softness and air permeability of the non-woven fabric.

High-pressure hydroentanglement: On JIELI's production line, a high-pressure water pump pressurizes water to hundreds of bars and sprays it onto the fiber web at a very high speed through a special nozzle. This process not only causes strong friction and entanglement between fibers, but also effectively removes excess water and air in the fiber web, making the structure tighter.

Multi-pass spunlace: In order to further enhance the strength and uniformity of the fiber web, JIELI's production line is usually equipped with multiple spunlace processes. The spunlace direction and pressure of each process can be adjusted as needed to ensure that the fiber web can be fully reinforced in all directions.

Dehydration and drying: After the spunlace is completed, the fiber web needs to be dehydrated to remove excess water, and then enter the drying area to quickly dry by hot air or infrared to maintain the softness and dimensional stability of the product.

Technical advantages and quality control

JIELI's technical advantages in the production of beauty care spunlace non-woven fabrics are not only reflected in advanced web laying and reinforcement technology, but also throughout the quality control of the entire production process:

High-precision inspection: After each process, JIELI will conduct strict quality inspections, including fiber uniformity, fiber web strength, appearance and feel after spunlace, etc., to ensure that each step meets the established standards.

Customized R&D: Relying on a research and development team composed of foreign experts, industry experts and senior engineers, JIELI is able to develop customized products based on the specific needs of customers, such as specific fiber ratios, thickness, air permeability, water absorption, etc., and provide rapid response services from drawings to samples.

Raw material control: Strict screening and quality control of raw materials are the cornerstones of JIELI's product quality. The company establishes long-term cooperative relationships with high-quality suppliers to ensure a stable supply and consistent quality of raw materials, providing strong guarantees for sustainable production.

Production capacity and supply stability: With two advanced imported semi-cross spunlace non-woven fabric production lines with an annual output of more than 10,000 tons, JIELI can not only meet the needs of large-scale procurement, but also flexibly adjust production plans to ensure the stability and timeliness of supply.

Beauty Care Spunlaced Nonwoven Fabric Suppliers

JIELI:

Source factory spot wholesale

Source factory spot wholesale

Jieli Textile Co., Ltd. is a company specializing in the research and development and production of spun lace nonwoven fabric products. We are China Wholesale Beauty Care Spunlaced Nonwoven Fabric Suppliers and OEM/ODM Beauty Care Spunlaced Nonwoven Fabric Company. The company is located in the Dama Yiyuan Entrepreneurship Park in Jiaxing, Zhejiang, covering an area of 30 acres with a building area of 50,000 square meters. It is equipped with two advanced imported semi-cross spun lace nonwoven fabric production lines, with an annual production capacity of up to 10,000 tons...

-

R&DOur R&D team is composed of highly qualified professionals, including foreign experts, industry ...

-

High Cost-effectiveness.The company's convenient geographical location and efficient management team have reduced transporta...

-

CapacityContinuous and reliable product supply, with ample production capacity, high control over raw materi...

News Center

-

2026-01-22

Introduction In the modern textile industry, fancy yarns are increasingly favored by designers and manufacturers due to their unique appearance and functionality. Compared to traditional single yarns, fancy yar... -

2026-01-15

Chemical fiber polyester yarn, as a widely used raw material in the textile industry, has gradually replaced natural fibers over the past few decades, becoming one of the most common textile products on the mar... -

2026-01-08

Sized non-woven fabric, as an important material in the modern textile industry, is widely used in packaging, home furnishings, medical applications, agriculture, and industrial filtration due to its unique pro...

Beauty Care Spunlaced Nonwoven Fabric Industry knowledge

English

English 中文简体

中文简体