Sized Non-woven Fabric: Fusion of innovative materials and wide applications

Posted by Admin | 01 Jun

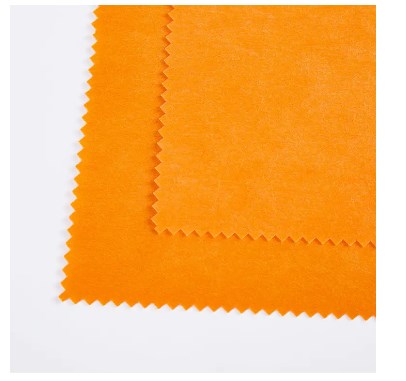

Sized Non-woven Fabric, as a specially treated non-woven fabric, has been widely used in many fields in recent years. Its unique fiber processing process gives it excellent strength, tensile strength and softness.

1. What is Sized Non-woven Fabric?

Sized Non-woven Fabric is a non-woven fabric that improves surface properties through sizing. Non-woven fabric is a non-woven fabric directly processed from fibers or fiber sheets, and usually has good air permeability and lightness. The sizing process is to form a protective film on the surface of the non-woven fabric by coating the sizing material, thereby enhancing its physical properties such as strength, wear resistance, and water resistance.

The main application of Sized Non-woven Fabric is to improve its surface properties so that it can adapt to more high-demand scenarios, such as in the fields of medical, home, automobile and industry, and plays an important role.

2. Production process of Sized Non-woven Fabric

The production process of Sized Non-woven Fabric can be roughly divided into the following steps:

Raw material selection and fiber preparation

First, it is necessary to select suitable fiber raw materials. Generally, synthetic fibers such as polyester and polypropylene are used. These fibers have good toughness and strength. Next, the fibers are preliminarily treated to adapt them to the subsequent non-woven fabric production process.

Non-woven fabric production

Non-woven fabric production generally adopts wet method, dry method, melt-blown method and other technologies to weave and bond the raw materials into cloth through different processes. This process ensures the basic form and performance of non-woven fabrics.

Sizing treatment

After the non-woven fabric is made, it enters the sizing treatment link. Common sizing agents include polyurethane, starch, acrylic acid, etc. These sizing agents can enhance the strength of the non-woven fabric surface and provide additional waterproof, oil-proof, antistatic and other functions.

Drying and finishing

The sizing non-woven fabric needs to be dried to remove excess water or solvent. Finally, through post-treatment processes such as hot pressing and ironing, ensure that the surface of the non-woven fabric is flat and smooth and meets the predetermined performance requirements.

3. Performance characteristics of Sized Non-woven Fabric

Sized Non-woven Fabric has shown many excellent properties due to its unique production process.

High strength and good tensile strength

Sizing treatment greatly improves the strength of non-woven fabrics, especially after physical treatment, the tensile strength is significantly enhanced. This makes sized non-woven fabrics perform well in high-intensity usage scenarios, such as industrial filtration, medical dressings and other fields.

Smooth surface and strong wear resistance

The surface of the sized non-woven fabric is smoother and has good wear resistance. It is particularly outstanding in many occasions that need to withstand repeated friction, such as cleaning products and wipes.

Waterproof and oil-proof performance

The sizing process can effectively improve the waterproof and oil-proof ability of non-woven fabrics. This makes it widely used in construction, automotive interiors and food packaging.

Good breathability and comfort

Although the surface has been treated with sizing, the breathability of sized non-woven fabrics is still good, and it feels soft and comfortable. Therefore, its application in clothing fabrics and medical and sanitary products is particularly important.

4. Application fields of Sized Non-woven Fabric

Due to its excellent performance, Sized Non-woven Fabric has been widely used in many fields.

Medical field

In the medical industry, sized non-woven fabrics are often used to produce masks, dressings, surgical gowns and other products. The sizing process can effectively improve the antibacterial, breathable and comfortable properties of non-woven fabrics, making them an ideal choice for medical and sanitary products.

Automotive industry

Sized non-woven fabrics play an important role in automobile manufacturing. For example, in the seat pads, door linings, carpets and other parts of the car interior, the use of sized non-woven fabrics can improve the durability and comfort of the material, and have certain waterproof and oil-proof functions.

Household products

In household products, sized non-woven fabrics are widely used in the production of household products such as bedding, curtains, carpets, sofas, etc. The softness and durability of sized non-woven fabrics make them ideal home fabrics.

Environmental protection and filtration materials

Another major application area of sized non-woven fabrics is in environmental protection and filtration materials. Its high strength and wear resistance make it increasingly used in air filtration, liquid filtration and wastewater treatment. For example, sizing non-woven fabrics are often used as filter media in industrial filters and air purifiers.

Packaging industry

In the packaging industry, especially in food packaging, sizing non-woven fabrics are used as packaging materials due to their waterproof and oil-proof properties. It can effectively ensure the freshness and quality of products, and is especially suitable for the packaging of fast-moving consumer goods and perishable goods.

With the continuous advancement of technology and changes in market demand, sizing non-woven fabrics will continue to develop and innovate in the future. In the future, sizing non-woven fabrics will tend to be environmentally friendly, functional and intelligent, and can play a role in more industries. Especially with the promotion of green environmental protection concepts, biodegradability and recyclability have become important directions for the development of non-woven fabrics.

+86-18058809000

+86-571 86218111

English

English 中文简体

中文简体